At some point I picked up some 3/4 sheets of pink foam insulation for our basement renovation. Tip: Strap these down very well in your pickup truck, or they become airborne at exactly 17 mph on the way back from the home center.

Other than the obvious, there are a few uses for leftover insulation around the shop, such as using it on the floor as a sacrificial surface for breaking down plywood with a circular saw. But what if you have more than you need and (like me) are too cheap to throw it away? How about an upgrade to your garage door?

I took a few scraps and lined the inside of my roll up door with the insulation. Cut carefully to size for a friction fit. Believe it or not, the table saw works great to cut this stuff. Another option is to simply score and snap like drywall. I doubt I'm adding much in the way of either thermal insulation or soundproofing, but every little bit helps. At least I didn't send the stuff to the landfill, and if I can keep even a little of the noise away from the neighbors then that's great too.

Now you may choose to stop there, but for some reason the big pepto pink garage door just wasn't my style. This is where I turned to an old geek trick I've used many times before. For about $12 per sheet you can get a product called tileboard at the home centers which is a pretty good replacement for whiteboard material. This stuff is probably intended to cover walls in single-wide trailers or gas station bathrooms, but nothing is too good for my shop! It's shiny, white and works fine with dry-erase markers. The core is Masonite, about 1/8" thick.

Again, I simply cut some tileboard panels to fit and covered up all the frilly pink stuff just like putting a pair of tidy whiteys over a thong - or so I would guess, anyway. My door panels had lips on the top and bottom so I was able to just bow out the insulation and whiteboard a little to pop them into place.

The door is now a great place to jot notes during a project, to work out dimensions, draw sketches, or make shopping lists for runs to the home center. I also threw another piece of tileboard on the wall behind the door into the house to make use of the space for full-on geekery.

What do you think? I'd love to hear it in the comments. Is this a good idea for your shop, or are you still just creeped out about the whole "thong" analogy?

Sunday, September 26, 2010

Wednesday, September 22, 2010

Hand Rail Part 2 - Getting Jiggy

Sorry for the bad pun, really.

In a previous post, I said the next step on my handrail project was to make a jig but I'm a big fat liar. Instead I went shopping for lumber and returned to the shop with a couple 16 foot 5/4x4's. I glued these together and used screws in what I thought was a safe spot on the back of the rail where the finger groove would be. Turned out I made a change later and had to fill the holes, but oh well.

Next step was to make the router jig. I will warn you in advance that I must have gone through 5 different versions of the jig, each time trying to battle an unexpected difficulty. In the end I was able to make it work but I now wonder if free-handing it may not have been a possible option. I probably couldn't get it as consistent as the router method though.

First step was to glue the scale pattern I printed to some hardboard and carefully cut out the profile using a jigsaw, file, and sanding blocks.

Next I used the template with a flush trim bit to make a couple sides from 1/2 Baltic birch plywood.

I assembled these with some straight sides into a box with a curved top, being careful to align the two curved parts.

Then using a straight bit with a bottom bearing, I removed material from the curved sides so that the jig could slide up and down the glued up railing blank. I used a chisel to square up the corners. Sharp eyed readers will notice a problem already, but not me!

My thinking was to put a fat 3/4" straight bit into the router, and then just follow the curves on the jig with the router freehand. I would go side to side for a few inches, then slide on down and repeat. Yeah, right. The picture below shows my first attempt. There are a few concerns. First of all, the angle of the router really mattered with the straight bit. rock a little too much and the bit really dug deep into the rail, leaving a round gouge. Second, take a look at the router in the picture above. See those holes that I ignored? They make it impossible to follow the 1/2 thick template - the holes kept bottoming out on the jig. Third, I had no way of seeing when to stop so I've already cut into the jig. Some of this is necessary to get the edge or the rail, but I had a lot more to go and wanted to make sure the jig made it.

Back to the drawing board! First I put a piece of polycarbonate on the base with some double stick tape to counteract the holes. Second, I switched to a "bowl and tray" router bit so the edges were curved and hopefully rocking the router slightly wouldn't dig into the rail. I actually tried again with just that setup, and it was still really hard to rotate the router exactly perpendicular to the curve. So I added the little concave curved ramps that had the opposite curve as the jig. Don't even ask how long it took me to make those. Finally, the two strips on the very sides of the poly base are there to stop me from going too far side to side and eating into the curved sides of the jig.

That worked pretty well, but I was still getting pretty lousy results going back and forth across the rail. I had visions of a perfectly curved surface, but each pass just wasn't precise enough to leave a smooth surface. It looked like I was making corn on the cob.

Finally I realized that I should be sliding the router along the rail, not across it. It takes me a while, but I get there! I put some double sided tape on the jig - which had seen better days by this time.

Then I just stuck the router on the jig, made a long pass on the rail, rotated a bit and repeated until I had hogged away most of the waste.

I was left with a rail with small ridges along the length, but these cleaned up pretty well with a palm sander.

After that, I made a pass along the bottom with a beading bit, and along the back with the bowl & tray bit again to carve out a recess for fingers to grip the handrail. Here is a shot of the railing on the stairs. It's just primed at this point, since I am out of trim paint.

In a previous post, I said the next step on my handrail project was to make a jig but I'm a big fat liar. Instead I went shopping for lumber and returned to the shop with a couple 16 foot 5/4x4's. I glued these together and used screws in what I thought was a safe spot on the back of the rail where the finger groove would be. Turned out I made a change later and had to fill the holes, but oh well.

Next step was to make the router jig. I will warn you in advance that I must have gone through 5 different versions of the jig, each time trying to battle an unexpected difficulty. In the end I was able to make it work but I now wonder if free-handing it may not have been a possible option. I probably couldn't get it as consistent as the router method though.

First step was to glue the scale pattern I printed to some hardboard and carefully cut out the profile using a jigsaw, file, and sanding blocks.

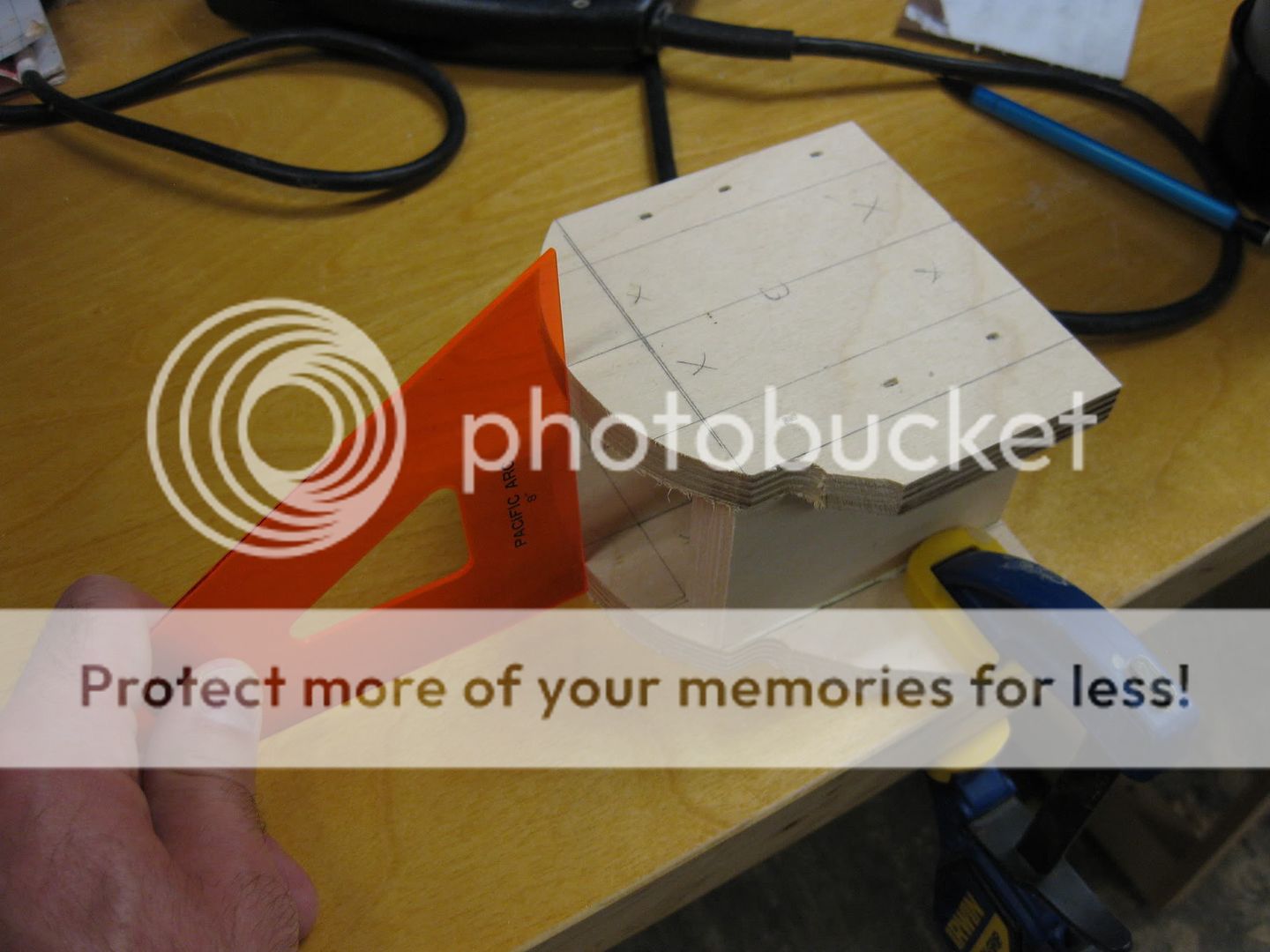

Next I used the template with a flush trim bit to make a couple sides from 1/2 Baltic birch plywood.

I assembled these with some straight sides into a box with a curved top, being careful to align the two curved parts.

Then using a straight bit with a bottom bearing, I removed material from the curved sides so that the jig could slide up and down the glued up railing blank. I used a chisel to square up the corners. Sharp eyed readers will notice a problem already, but not me!

My thinking was to put a fat 3/4" straight bit into the router, and then just follow the curves on the jig with the router freehand. I would go side to side for a few inches, then slide on down and repeat. Yeah, right. The picture below shows my first attempt. There are a few concerns. First of all, the angle of the router really mattered with the straight bit. rock a little too much and the bit really dug deep into the rail, leaving a round gouge. Second, take a look at the router in the picture above. See those holes that I ignored? They make it impossible to follow the 1/2 thick template - the holes kept bottoming out on the jig. Third, I had no way of seeing when to stop so I've already cut into the jig. Some of this is necessary to get the edge or the rail, but I had a lot more to go and wanted to make sure the jig made it.

Back to the drawing board! First I put a piece of polycarbonate on the base with some double stick tape to counteract the holes. Second, I switched to a "bowl and tray" router bit so the edges were curved and hopefully rocking the router slightly wouldn't dig into the rail. I actually tried again with just that setup, and it was still really hard to rotate the router exactly perpendicular to the curve. So I added the little concave curved ramps that had the opposite curve as the jig. Don't even ask how long it took me to make those. Finally, the two strips on the very sides of the poly base are there to stop me from going too far side to side and eating into the curved sides of the jig.

That worked pretty well, but I was still getting pretty lousy results going back and forth across the rail. I had visions of a perfectly curved surface, but each pass just wasn't precise enough to leave a smooth surface. It looked like I was making corn on the cob.

Finally I realized that I should be sliding the router along the rail, not across it. It takes me a while, but I get there! I put some double sided tape on the jig - which had seen better days by this time.

Then I just stuck the router on the jig, made a long pass on the rail, rotated a bit and repeated until I had hogged away most of the waste.

I was left with a rail with small ridges along the length, but these cleaned up pretty well with a palm sander.

After that, I made a pass along the bottom with a beading bit, and along the back with the bowl & tray bit again to carve out a recess for fingers to grip the handrail. Here is a shot of the railing on the stairs. It's just primed at this point, since I am out of trim paint.

Maybe now my mother in law will give me a break next time she comes over! She's been waiting for this for months!

Monday, September 06, 2010

How accurate should a SketchUp model be?

In the October 2010 issue of Popular Woodworking Magazine there is a letter about modeling drawers in SketchUp. The reader asks how to model the small clearances required to make sure the drawers ride smoothly in their openings. In "meatspace" this typically means the drawers are 1/32 or 1/16 undersized to the openings. Bob Lang answered this question well, but in my opinion missed the most obvious response: Why the heck would you need to model to this level of detail?

Look, I know more than most how tempting it can be to get every little detail correct in a SketchUp model. I've spent time tweaking little bits and pieces to make sure they were just right, believe me. While designing projects I can have multiple generations of a design, exploring new options and branching out into infinite possibilities. So take it from somebody who has fallen down that rabbit hole - you have to know when to stop modeling and start building.

These days I am trying to remind myself that the goal is to make projects, not models. My ability to create precision in SketchUp are far beyond my abilities for precision in the shop. Wood moves with the seasons, small variations in tool setups introduce randomness during a build, and sometimes designs get changed on the fly.

Here are a few questions I try to ask myself as I am making a model to ensure I am not sinking deeper into OCD territory.

Look, I know more than most how tempting it can be to get every little detail correct in a SketchUp model. I've spent time tweaking little bits and pieces to make sure they were just right, believe me. While designing projects I can have multiple generations of a design, exploring new options and branching out into infinite possibilities. So take it from somebody who has fallen down that rabbit hole - you have to know when to stop modeling and start building.

These days I am trying to remind myself that the goal is to make projects, not models. My ability to create precision in SketchUp are far beyond my abilities for precision in the shop. Wood moves with the seasons, small variations in tool setups introduce randomness during a build, and sometimes designs get changed on the fly.

Here are a few questions I try to ask myself as I am making a model to ensure I am not sinking deeper into OCD territory.

- Will the extra level of detail make it easier to build the real piece? By all means, if it makes things easier in the shop then add it to the model. I am a strong believer in modeling details on joinery, curves, edge profiles, etc. as long as they make the time in the shop easier. An exploded view of the project with a few key dimensions is invaluable to me as I build. But leave out things that make no difference in the shop.

- Will the final dimension of the wood match the SketchUp model? SketchUp is great at providing dimensions for raw stock. Suppose you have a door rail that will be mortise & tenoned into the stile. By all means, add the two tenons to the ends of the rail and use SketchUp to measure the total length of the rail. But by the time you need to know the dimensions of the door panel, measuring the actual meatspace door is the best way to go. A little variability could have crept in and suddenly the dimension of the panel in SketchUp doesn't match the door you built. Until you have a CNC machine just spitting out all you project parts, you have to know when to abandon the perfection of the SketchUp planned dimensions.

- Does the design of the piece require a more detailed model? If I am trying a new type of joint or I want to see how a curve would look, I add more detail until my question is answered. Otherwise, keep it simple. For example, when designing a piece with drawers I will often create a simple rectangle to fill the drawer opening instead of modeling a full dovetailed drawer. Even a drawer-sized box is easy to make and fill the hole. Until I need details about the drawer there is no need to model it beyond that point. It's a heck of a lot easier to explore the overall size and shape of the piece this way.

Labels:

Accuracy,

nutty modeling,

OCD,

Pop Woodworking,

SketchUp

Subscribe to:

Posts (Atom)